hard anodizing aluminum diy

The anodizing of aluminum is a popular process that improves the metals durability resistance to corrosion and scratching. Standard dyed Type II anodize is generally around 075 - 10 mil thousands of an inch thickness.

Anodising Aluminium At Home Results

Hardcoat Type III Anodizing System.

. Fizz the aluminium in caustic soda solution until it looks a nice grey colour. Im getting ahead of myself though. Cover your working area in something disposable.

Prepare your aluminium piece. In the production process of aluminum profile the conductive contact area of the fixture and the mark of the fixture shall be minimized. Normally for Type II anodising we have our acid bath around 15-20 degrees.

But i would think that for your conditions this process would protect as well unless the conditions are really brutalDepending on the alloy it will be dark brown or dark greyDont let it touch the aluminium part at the anode. This will be for type II anodizing type 2 anodizing. Start the water at about 95C and bring it to a simmering boil over the course of a few minutes.

Hard Anodizing Aluminum Diy Before anodizing however we need to remove the natural aluminum oxide layer from the metal surface. This will give a nice even surface finish that will look good after anodizing. How to Anodize Aluminum the DIY Way Scotch-Brite the Aluminum.

Put on your safety glasses. Hardcoat Type III aluminum anodizing is a coating frequently found on firearms and aircraft parts. The temperature often rises during the anodising process.

To anodize aluminum set up a plastic tub in a well-ventilated area and put your power supply on a non-flammable surface. Step by Step home DIY anodizing of aluminium Mix up 10 to 20 Sulphuric Acid solution with pure distilled water. It is a much thicker and harder coating than a standard anodize coating and is not usually dyed.

It is generally referred to as an engineering hard due to the fact that the oxide has been found to be suited for applications where the hardness and increased oxide thicknesses are an advantage. Since anodizing only grows at 90 degree angles to the aluminum surface it is easy to strike the edge and break off the anodized cells. Best diy anodizing kit from diy multi color anodizing of aluminum with tifoo anodising.

You can buy anodizing sealers to add to the water but Ive not needed this. If you absolutely require Type-III remember you will have to live with the gray-blackish color as you probably wont be able to successfully dye it it can be done. Anodized Aluminum Handrail Stairs Kit Stainless Steel Look 7 Ft And 197 Diameter Aluminum Handrail Stair Kits Handrail.

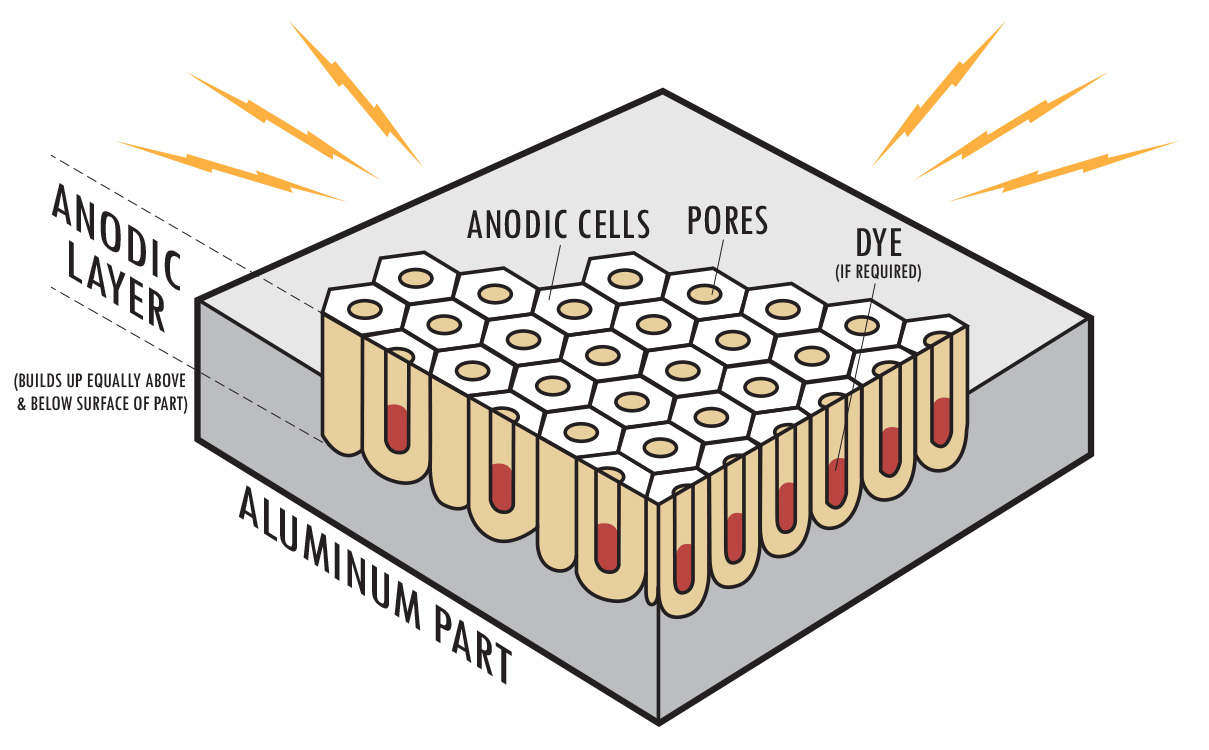

That is the type of anodizing that takes dye well and is typically used mainly for cosmetic purposes but also adds a hard aluminum oxide coating to the part that is very corrosion resistant as well as wear resistant and has electrical insulating properties. Hard anodising is performed with a weaker solution of sulfuric acid and a lower temperature acid bath. Anodizing parts in my garageI am an amazon affiliate and make profits from the links belowRed dyehttpsamznto2JoKYnhBlue dyehttpsamznto2Hvtsw5Hot.

Get your respirator within hands reach. You might want to hold the part in hot steam for a while before you put it in the water. In addition to the reasons above aluminum anodizing also offers some aesthetic.

For type III hard anodizing the temperature must be only 2-4C. In the production process the temperature of sulfuric acid anodizing solution should be controlled within a. Next tie one end of a 12-gauge aluminum wire to your anode wrap the middle of the wire around a piece of wood and set a.

It is a much thicker and harder coating than a standard anodize coating and is not usually dyed. Techmetals has over 50 years experience in titanium and aluminum anodize assisting a variety of industries like the medical aerospace and automotive fields for instance. Type III hard anodizing is an anodizing process that forms an extremely hard abrasion resistant porous oxide on aluminum.

Of course there is a little more involved. How do you hard anodize aluminum at home. I have an unconfirmed suspicion that commerical anodizing dyes need a special sealer.

It is generally referred to as an engineering hardcoat due to the fact that the oxide has been found to be suited for applications where the hardness and increased oxide thicknesses are an advantage. Hardcoat Type III Anodizing System Hardcoat Type III aluminum anodizing is a coating frequently found on firearms and aircraft parts. Standard dyed Type II anodize is generally around 075.

Type III hardcoat anodizing is an anodizing process that forms an extremely hard abrasion resistant porous oxide on aluminum.

How To Anodize Aluminum At Home Make It From Metal

Diy Aluminum Anodizing In 10 Steps Sendcutsend

Shopbuilt How To Anodize Aluminum Youtube

Category Anodizing Aluminum Observations

Mini Slingshot How To Anodize Aluminum Diy Giaco Giaco Youtube

Everything You Need To Know About Anodizing Aluminum 3erp

Diy Anodize Aluminum At Home With A Battery Charger Youtube

Anodising Aluminium At Home Results

Diy Aluminium Anodising How To Improve Your Anodising

Homemade Anodizing Automatic Artisan

How To Anodize Aluminum My Approach On Diy Small Scale Anodizing By Deeworks Youtube

Anodizing Aluminium At Home First Experiments

Diy Aluminum Anodizing In 10 Steps Sendcutsend

Diy How To Anodize Aluminum At Home Youtube

Anodizing Aluminium At Home First Experiments

How To Anodize Aluminum The Federal Group Usa

Diy Manual Mechanic Anodize The Aluminum Diy Coloring

How To Anodize Aluminum Parts Easily In The Home Shop Msfn Youtube